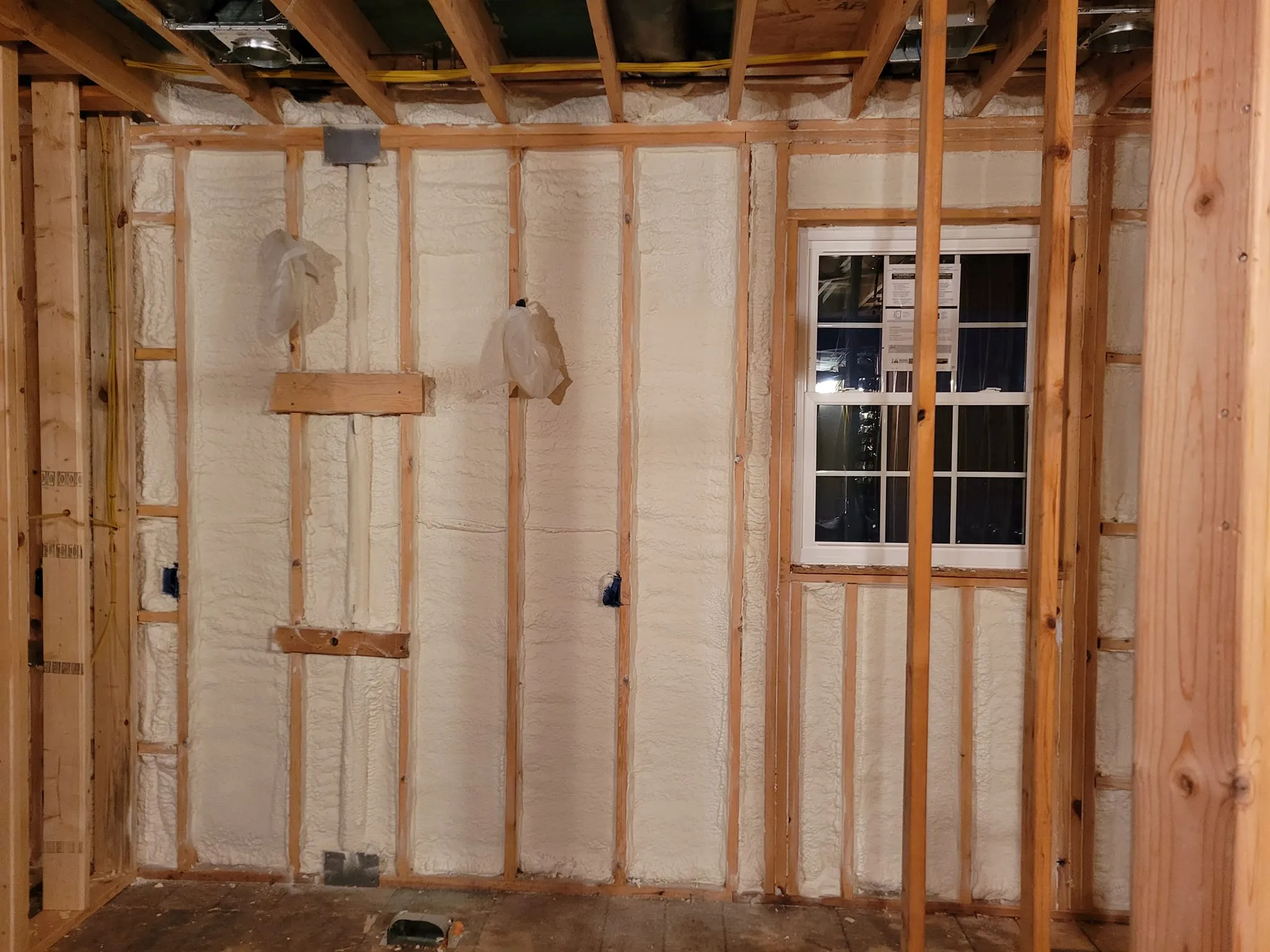

Sterling Heights homes experience significant energy savings, enhanced comfort, and superior moisture control when upgraded with spray foam insulation. This advanced insulation solution delivers exceptional air sealing properties that reduce energy costs by 20-50% annually while creating consistent indoor temperatures throughout Michigan’s challenging climate conditions. The closed-cell spray foam performs particularly well in Sterling Heights’ humid summers and harsh winters, preventing condensation issues that commonly affect traditional insulation materials.

Professional spray foam installation transforms home performance by eliminating air leaks, reducing utility bills, and creating healthier indoor environments. Based on extensive field experience across southeastern Michigan, homes treated with spray foam maintain more stable temperatures, experience fewer moisture-related problems, and achieve superior long-term durability compared to conventional insulation methods.

Spray foam insulation delivers measurable energy efficiency improvements that directly impact monthly utility costs. The material expands upon application, filling gaps and cracks that allow conditioned air to escape, creating an effective thermal barrier throughout the building envelope.

Sterling Heights homes typically lose 25-40% of conditioned air through uncontrolled air leakage, according to the Department of Energy’s residential building assessments. Spray foam application reduces this loss to under 5%, resulting in substantial cost savings over time.

Bonus Tip: Schedule spray foam installation during moderate weather conditions (50-85°F) for optimal curing and expansion characteristics. This timing ensures maximum adhesion and performance longevity.

| Insulation Type | R-Value per Inch | Air Sealing | Moisture Barrier | Lifespan |

|---|---|---|---|---|

| Closed-Cell Spray Foam | 6.0-7.0 | Excellent | Yes | 80+ years |

| Open-Cell Spray Foam | 3.5-4.0 | Good | No | 80+ years |

| Fiberglass Batts | 2.2-4.3 | Poor | No | 10-25 years |

| Cellulose | 3.1-3.8 | Fair | No | 20-30 years |

Michigan’s continental climate presents unique challenges requiring robust insulation solutions. Summer humidity levels averaging 70-80% combined with winter temperatures dropping below 15°F create demanding conditions for building envelope performance.

Closed-cell spray foam prevents moisture infiltration that leads to mold growth, wood rot, and structural damage common in southeastern Michigan homes. The material’s vapor barrier properties eliminate condensation within wall cavities, addressing a primary concern for local homeowners.

Technical Performance Specifications

| Performance Metric | Closed-Cell Value | Open-Cell Value | Building Code Requirement |

|---|---|---|---|

| R-Value | 6.5/inch | 3.7/inch | R-38 attic minimum |

| Permeance Rating | 0.8 perms | 16 perms | <1 perm for vapor barriers |

| Compressive Strength | 35 PSI | 0.5 PSI | Varies by application |

| Adhesion Strength | 25 PSI | 5 PSI | Project-specific |

Market research from the Insulation Contractors Association indicates that 68% of spray foam installations in Michigan focus on air sealing applications, with homeowners prioritizing energy cost reduction as the primary motivation for upgrades.

Spray foam installation represents a permanent building improvement that maintains effectiveness throughout its service life. Unlike traditional insulation materials that settle, degrade, or require replacement, spray foam retains its thermal properties and structural integrity for decades.

Bonus Tip: Document spray foam installation with before-and-after thermal imaging to verify complete coverage and identify any missed areas requiring attention.

The National Association of Home Builders reports that spray foam insulation adds an average of $2,500-4,000 to home resale value while reducing annual energy costs by $400-800 for typical Sterling Heights properties.

Evaluate your home’s specific needs before selecting spray foam applications. Existing insulation condition, air leakage patterns, and moisture concerns influence the most effective installation approach for your property.

Professional assessment identifies problem areas requiring attention beyond insulation, including ductwork modifications, ventilation adjustments, and structural repairs. Address these issues before spray foam application to maximize performance benefits.

Consider seasonal timing for installation projects. Spring and fall months provide optimal weather conditions for spray foam curing while allowing adequate ventilation during application procedures.

Budget planning should account for comprehensive air sealing rather than partial applications. Complete building envelope treatment delivers significantly better results than isolated improvements to individual areas.

Bonus Tip: Plan electrical and plumbing work before spray foam installation, as accessing utilities becomes challenging after application completion.

Colony Insulation provides comprehensive spray foam applications tailored to Sterling Heights home requirements. Each installation combines technical expertise with quality materials to deliver lasting performance improvements.

Spray Foam Insulation: Complete air sealing and thermal barrier installation for new construction and retrofit applications, addressing specific performance goals for energy efficiency and comfort enhancement.

Attic Insulation: Specialized spray foam treatment for attic spaces, creating effective thermal boundaries while preventing ice dam formation during winter months.

Crawl Space Encapsulation: Moisture control and thermal improvement solutions for crawl space areas, eliminating humidity problems and improving overall home performance.

Air Sealing Services: Targeted spray foam applications for specific air leakage areas, providing cost-effective improvements without full-scale insulation replacement.

Clear the installation area of stored items, ensure adequate ventilation access, and complete any electrical or plumbing modifications before application begins.

Initial curing occurs within minutes, but full chemical cure requires 24-48 hours depending on temperature and humidity conditions during installation.

Yes, spray foam adheres to most existing materials, though removing loose or damaged insulation often improves overall results and cost-effectiveness.

Professional installation includes proper ventilation protocols to ensure safe application conditions and optimal curing environment for the spray foam material.

Sterling Heights homeowners benefit most from spray foam when addressing comprehensive building envelope improvements rather than isolated problem areas. Complete air sealing delivers superior results compared to partial applications, creating measurable improvements in comfort, energy efficiency, and long-term building durability.

Evaluate your specific situation considering current energy costs, comfort concerns, and long-term homeownership plans. Professional assessment provides accurate cost-benefit analysis tailored to your property’s unique characteristics and performance requirements.

Transform your Sterling Heights home’s performance with professional spray foam insulation solutions. Colony Insulation brings extensive experience and proven techniques to deliver lasting improvements in energy efficiency, comfort, and indoor air quality.

Contact Colony Insulation at (586) 850-1442 or [email protected] to schedule a comprehensive home assessment. Professional evaluation identifies the most effective spray foam applications for your specific needs while providing accurate project estimates and timeline expectations.

Spray foam performs well across all climate zones, with specific formulations designed for varying temperature and humidity conditions throughout the year.

Initial installation costs are higher, but energy savings and longevity typically result in positive return on investment within 3-5 years for most applications.

Removal requires specialized equipment and techniques, making careful planning important before installation to accommodate future modification needs.

Spray foam requires minimal maintenance once properly installed, though periodic inspection ensures continued performance and identifies any damage requiring repair.

Properly installed spray foam improves indoor air quality by reducing outdoor air infiltration and preventing moisture-related mold growth within building cavities.