Foam insulation delivers exceptional energy savings in Shelby homes by creating an airtight thermal barrier that reduces heating and cooling costs by 15-50% annually. This high-performance insulation material expands to fill gaps and cracks that traditional insulation cannot reach, effectively eliminating air leaks that account for 25-40% of residential energy loss according to the Department of Energy.

The superior sealing properties of foam insulation Shelby residents rely on make it particularly effective in the area’s climate, where temperature fluctuations demand consistent indoor comfort. Professional installation ensures proper application density and coverage, maximizing energy efficiency.iency while preventing moisture issues that can compromise indoor air quality and structural integrity.

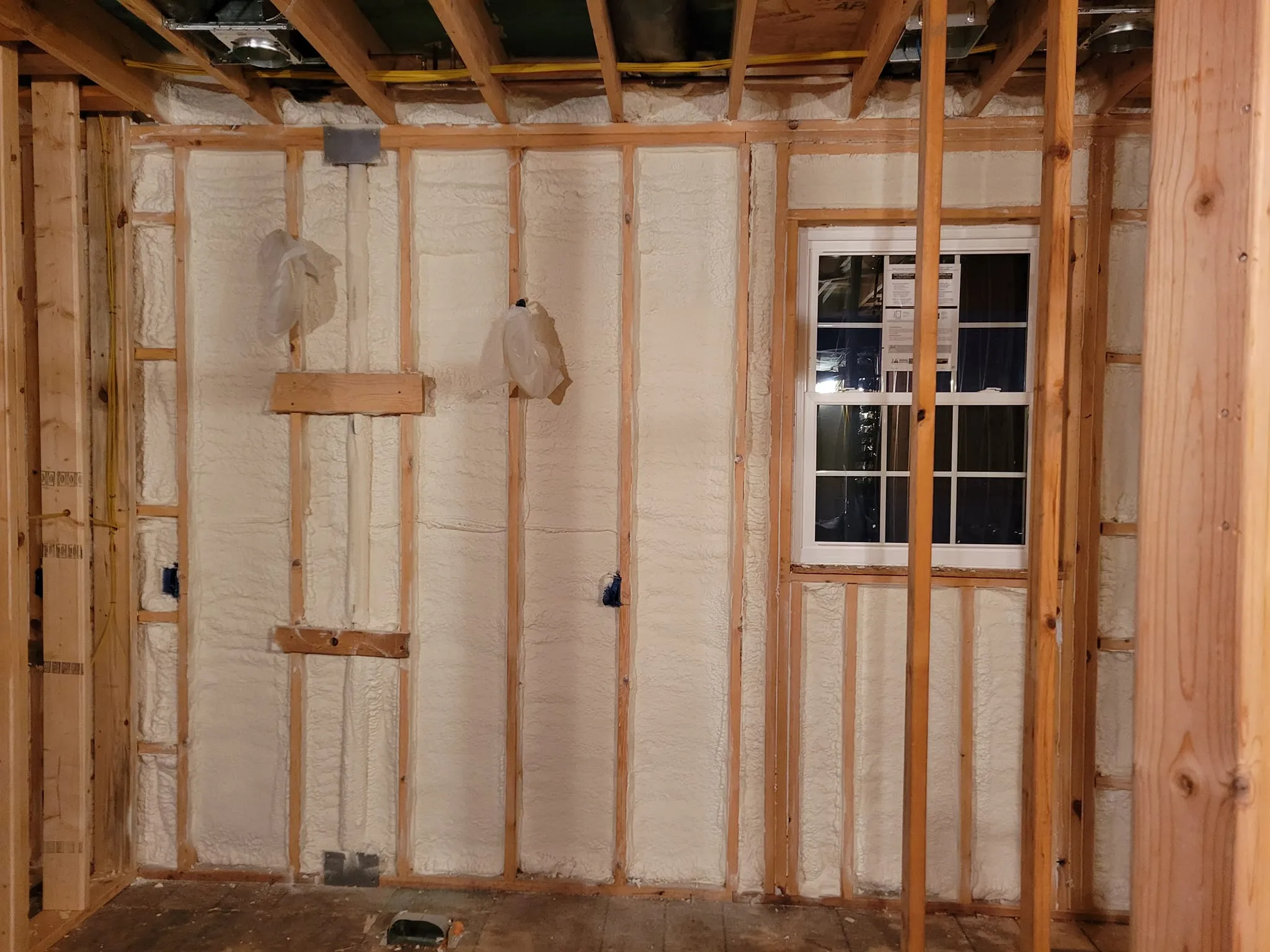

Foam insulation outperforms traditional materials through its unique expansion characteristics and superior R-value per inch. When applied, the material expands up to 100 times its liquid volume, creating a seamless barrier that conforms to irregular surfaces and penetrates small crevices where air leakage typically occurs.

The thermal performance varies significantly between foam types, with closed-cell foam providing the highest insulation value and moisture resistance. Open-cell foam offers excellent sound dampening properties while maintaining strong thermal performance at a lower cost point.

| Foam Type | R-Value per Inch | Air Sealing | Moisture Barrier | Sound Reduction |

|---|---|---|---|---|

| Closed-Cell | 6.0-7.0 | Excellent | Yes | Good |

| Open-Cell | 3.5-4.0 | Excellent | No | Excellent |

| Spray Polyurethane | 6.5-8.0 | Superior | Yes | Good |

Bonus Tip: Check for existing air leaks using an infrared thermometer before foam installation. Target areas around electrical outlets, plumbing penetrations, and rim joists where energy loss concentrates.

Foam insulation generates measurable energy savings through multiple mechanisms beyond basic thermal resistance. The air sealing properties eliminate convective heat transfer, while the continuous barrier prevents thermal bridging that reduces overall wall assembly performance.

Research from Oak Ridge National Laboratory demonstrates that foam insulation can reduce energy consumption by 20-50% compared to traditional fiberglass Bat insulation in similar applications. The actual savings depend on existing insulation levels, home construction details, and local climate conditions.

| Application Area | Potential Energy Savings | Payback Period |

|---|---|---|

| Attic | 15-25% | 3-5 years |

| Walls | 10-20% | 5-7 years |

| Crawl Space | 8-15% | 4-6 years |

| Basement | 12-18% | 4-6 years |

The National Association of Home Builders reports that properly installed foam insulation maintains its performance characteristics for 20-30 years without settling or degrading, ensuring long-term energy savings throughout its lifespan.

Shelby’s climate patterns require specific attention to moisture management and seasonal temperature variations. Foam insulation installation timing affects cure rates and final performance, with optimal conditions occurring when ambient temperatures range between 60-80°F and relative humidity stays below 85%.

Temperature cycling in Shelby creates expansion and contraction stresses that foam insulation accommodates better than rigid materials. The flexible nature of cured foam prevents cracking and separation that can compromise thermal performance over time.

Bonus Tip: Schedule foam insulation installation during moderate weather periods to ensure proper curing. Extreme temperatures or high humidity can affect the chemical reaction and final insulation properties.

Evaluate your home’s ventilation system before foam insulation installation, as the increased airtightness requires adequate mechanical ventilation to maintain indoor air quality. Older homes may need ventilation upgrades to prevent moisture buildup and ensure healthy indoor environments.

Consider the long-term implications of foam insulation’s permanence. Unlike removable insulation types, foam creates a permanent installation that becomes integral to the building structure. Future modifications or repairs require specialized removal techniques that add complexity and cost.

Assess existing electrical systems for compatibility with foam insulation. The expansion process can affect electrical boxes and wiring if not properly protected during installation. Coordinate with electrical contractors for any necessary modifications before foam application.

Colony Insulation provides comprehensive foam insulation solutions tailored to Shelby’s specific climate requirements and building characteristics:

Bonus Tip: Combine foam insulation with programmable thermostats and sealed ductwork for maximum energy savings. The improved building envelope allows HVAC systems to operate more efficiently and maintain consistent temperatures with less energy consumption.

Foam insulation represents a long-term investment in energy efficiency and comfort that pays dividends through reduced utility costs and improved indoor environments. The initial cost premium over traditional insulation materials typically recovers within 3-7 years through energy savings, while providing enhanced comfort and air quality benefits throughout the building’s lifespan.

Consider your specific goals for energy savings, comfort improvement, and long-term building performance when evaluating foam insulation options. The permanent nature of foam insulation makes it an excellent choice for homeowners planning to remain in their homes long-term or seeking to maximize property value through energy efficiency improvements.

Proper foam insulation installation requires specialized equipment, training, and experience to achieve optimal results and safety standards. Colony Insulation brings proven expertise in foam insulation applications throughout Shelby, ensuring installations meet manufacturer specifications and building codes while maximizing energy performance.

Contact Colony Insulation at (586) 488-2928 or [email protected] to schedule a comprehensive energy assessment and discuss foam insulation options tailored to your specific needs and budget requirements.

Properly installed and cured foam insulation does not emit harmful chemicals or affect indoor air quality. The curing process eliminates volatile compounds, leaving an inert material that actually improves air quality by preventing outdoor pollutants from entering through air leaks.

Most residential foam insulation projects complete within 1-2 days, depending on the scope and area coverage. The material cures quickly, allowing normal building occupancy within 24 hours of application.

Foam insulation can be applied over existing materials in many situations, though removing old insulation often provides better results. The decision depends on the condition and type of existing insulation, along with available space constraints.

Foam insulation requires minimal maintenance once properly installed. Periodic visual inspections for damage or settling help identify potential issues, though properly installed foam insulation typically maintains performance for decades without intervention.